25

2025

-

08

15 Reasons You Should be Talking About Coreless Motors

Key words:

Discover 15 reasons coreless motors matter for robotics, aerospace, and medical tech—lighter, faster, efficient, and reliable.

Author:

KESHUO

- 1. What Exactly Is a Coreless Motor?

- 2. High Speed Coreless Motor Technology

- 3. Ultra-Lightweight Design

- 4. Low Inertia for Fast Response

- 5. Reduced Cogging and Smoother Motion

- 6. Energy Efficiency and Lower Power Loss

- 7. Compact Size with High Power Output

- 8. Precision Control in Robotics

- 9. Reliability in Harsh Environments

- 10. Versatility Across Industries

- 11. Coreless DC Motor vs. Brushless Coreless Motor

- 12. Future Trends in Development

- 13. Cost Efficiency Over the Long Run

- 14. Quiet Operation Benefits

- 15. Why Engineers Prefer Coreless Motors

- FAQ

In modern engineering, performance demands are rising faster than ever. From precision surgical tools to aerospace actuators and advanced robotics, industries require motors that deliver lightweight design, high responsiveness, and maximum efficiency. Meeting these requirements is where the coreless motor stands out.

Unlike conventional iron-core motors, which rely on laminated steel in their windings, the coreless motor eliminates the iron core entirely. This structural change results in lower inertia, smoother motion, and significantly higher energy efficiency. Engineers can now design systems that react faster, run cooler, and operate more reliably—even under demanding conditions.

Today, coreless dc motors, brushless coreless motors, and high speed coreless motors are not just optional upgrades; they are critical components driving innovation in robotics, aerospace mechanisms, and medical technology. In the following sections, we’ll explore 15 compelling reasons why coreless motors are reshaping industries worldwide—and why forward-looking engineers should be talking about them now.

1. What Exactly Is a Coreless Motor?

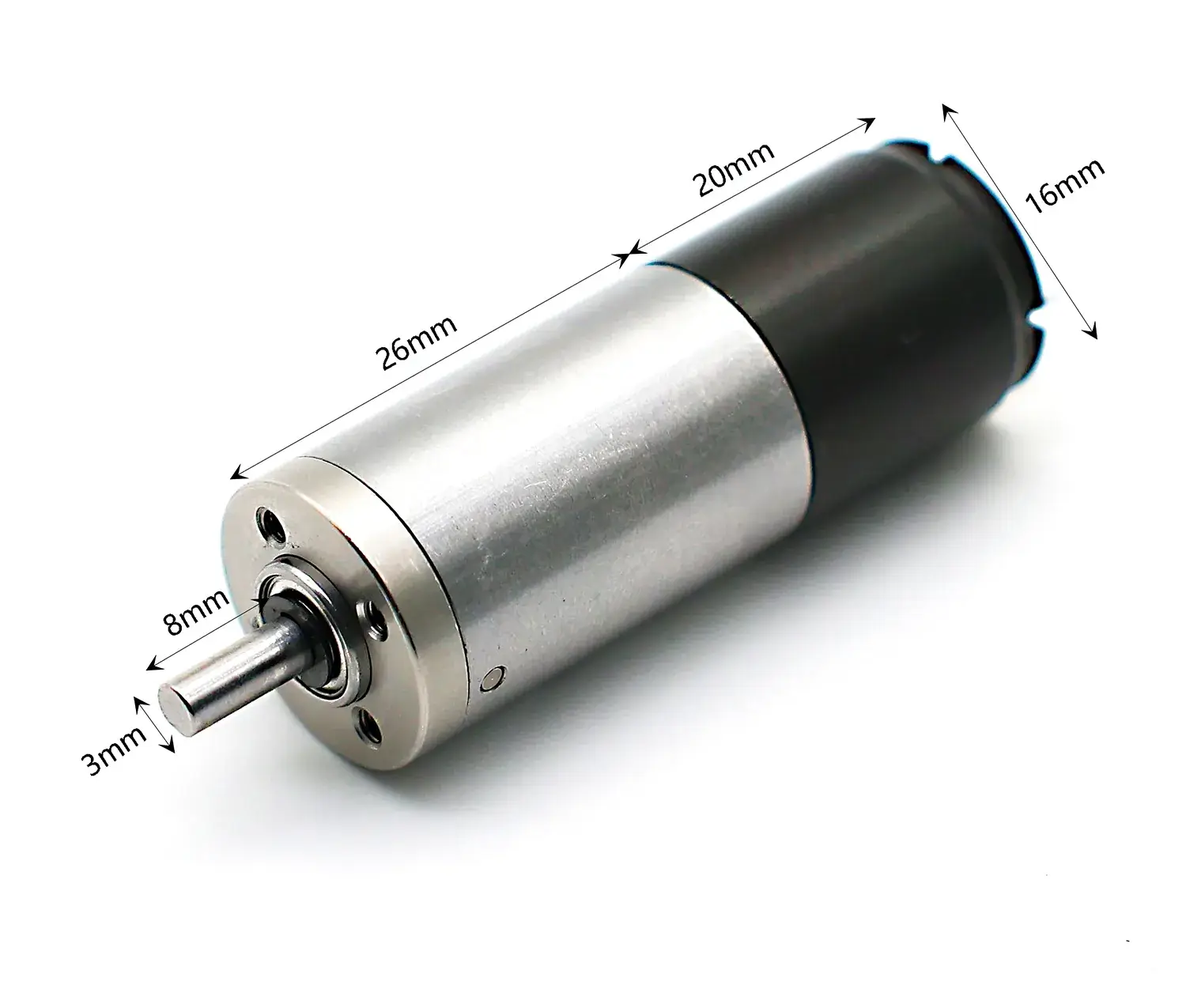

A coreless motor is a type of electric motor where the armature winding is constructed without a laminated iron core. Instead of being wound around a heavy iron stack, the copper coils are formed into a self-supporting, basket-shaped structure that sits directly inside the magnetic field. This unique architecture removes the mass and magnetic drag typically found in traditional cored designs.

The benefits are immediate:

Lower Inertia: Without the iron core, the rotor is much lighter, allowing rapid acceleration and deceleration.

Higher Efficiency: The absence of iron reduces eddy current losses and hysteresis losses, which means less wasted energy and less heat generation.

Compact and Lightweight: Coreless motors achieve a superior power-to-weight ratio, which is critical in applications where size and portability matter.

This is why coreless dc motors are widely integrated into devices such as medical hand tools, portable pumps, precision cameras, and small drones. Every gram counts in these industries, and the lightweight, efficient design of the coreless motor provides a competitive advantage that traditional iron-core motors simply cannot match.

2. High Speed Coreless Motor Technology Explained

Traditional iron-core motors encounter limitations when pushed to extremely high rotational speeds. The presence of an iron core increases the rotor mass, which in turn raises inertia, heat buildup, and mechanical stress. At elevated revolutions, these drawbacks lead to efficiency losses, noise, and even premature motor failure.

By contrast, a high speed coreless motor is engineered to overcome these constraints. With its lightweight, coreless rotor, the motor can achieve tens of thousands of revolutions per minute (RPM) while maintaining thermal stability. The self-supporting coil structure not only reduces weight but also improves heat dissipation, preventing the hot spots and energy losses common in cored motors.

Key advantages include:

Superior Thermal Management: The open winding design promotes better airflow and reduces heat accumulation, enabling sustained high-speed operation.

Rapid Acceleration: Low inertia allows the motor to reach target speeds almost instantly, which is critical in applications requiring fast response times.

Stable Performance: Even at extreme RPM, vibration and torque ripple are minimized, ensuring smooth and reliable operation.

These properties make the high speed coreless motor indispensable in fields where both speed and precision are mandatory. In robotics, they enable dynamic movement with precise control. In drones, they provide powerful thrust while keeping weight low. And in medical devices such as dental drills or surgical tools, they ensure consistent high-speed rotation that improves both accuracy and patient outcomes.

3. Ultra-Lightweight Design

One of the most striking advantages of the coreless motor is its dramatically reduced weight compared to traditional iron-core designs. Because the rotor does not carry heavy laminated steel, it can be engineered in a thin, basket-like or cylindrical structure that is both robust and extremely light. In many cases, a coreless rotor can weigh up to 50% less than its cored counterpart, without sacrificing performance.

This weight reduction translates into several engineering benefits:

Improved Power-to-Weight Ratio: Designers can achieve higher torque and speed without increasing the overall size or mass of the motor.

Lower Energy Consumption: Lighter components require less power to move, extending battery life in portable and aerospace systems.

Enhanced Ergonomics: Devices powered by lighter motors are easier to handle, reducing operator fatigue in medical and industrial environments.

The lightweight nature of brushless coreless motors makes them particularly attractive in aerospace applications, where every gram of weight matters for fuel efficiency and payload optimization. Similarly, in handheld medical instruments such as surgical drills, saws, and precision handpieces, reduced motor mass allows doctors to operate for extended periods with greater control and less strain. This is a critical factor in procedures where precision and endurance can directly affect patient outcomes.

By combining compact dimensions with low weight, the coreless motor provides engineers with an unparalleled degree of design flexibility. Whether in satellites, robotic systems, or medical tools, its lightweight architecture opens doors to performance levels that traditional iron-core motors cannot achieve.

4. Low Inertia for Fast Response

Inertia is one of the key limitations in traditional motor design. The iron core inside a conventional rotor adds significant mass, which slows down the motor’s ability to accelerate or decelerate. In fast-moving mechanical systems, this delay can create inefficiencies, imprecise movements, and even instability.

A coreless dc motor eliminates this issue by removing the iron mass from its rotor. With only a lightweight, self-supporting coil in place, the motor achieves exceptionally low inertia. This allows for lightning-fast acceleration and deceleration, giving engineers a level of responsiveness that is difficult to achieve with iron-core motors.

The benefits of low inertia are particularly important in applications requiring speed and precision:

Camera Gimbals and Stabilizers: A coreless motor can react instantly to motion changes, keeping cameras perfectly steady for professional-grade imaging.

Robotic Joints and Actuators: In robotics, split-second movements demand motors that respond quickly and predictably. Coreless designs ensure robotic arms move smoothly and stop exactly where intended.

Precision Instruments: Devices like laboratory automation systems or optical positioning units rely on rapid corrections, made possible by the motor’s quick response time.

By offering a near-instantaneous reaction to control signals, the coreless dc motor enhances overall system stability and precision. This is why they are the preferred choice for high-performance gimbals, advanced robotic systems, and any application where fast dynamic response is essential.

5. Reduced Cogging and Smoother Motion

One of the persistent drawbacks of traditional iron-core motors is cogging torque—the uneven, jerky motion caused when permanent magnets align with the laminated teeth of the iron core. This effect is especially noticeable at low speeds, where precise control is required. Cogging not only reduces positioning accuracy but can also generate unwanted vibration and noise.

The coreless motor effectively eliminates this problem. With no iron teeth in the rotor, there is no magnetic “snapping” effect. Instead, the motor delivers a near-perfect linear torque output across the entire rotation range. The result is exceptionally smooth, jitter-free motion, even at very low operating speeds.

This property is highly valued in precision-driven industries:

Filmmaking and Cinematography: Professional camera systems use coreless dc motors in gimbals and stabilizers, ensuring flawless camera tracking without micro-vibrations that could ruin a shot.

Optical Instruments: From microscopes to laser alignment devices, smooth motor motion guarantees accurate, repeatable positioning at the microscopic level.

Medical Robotics: Surgical robots rely on smooth torque output to avoid sudden movements, which could compromise delicate procedures.

By reducing cogging torque, the coreless motor provides engineers with motion that is both smooth and controllable, unlocking applications that demand absolute precision. Whether in high-end film production, laboratory automation, or advanced medical systems, this advantage makes the brushless coreless motor and coreless dc motor indispensable in today’s precision technologies.

6. Energy Efficiency and Lower Power Loss

In today’s portable and battery-powered world, every watt of energy matters. Traditional iron-core motors tend to waste power through eddy current losses, hysteresis losses, and excess heat buildup in the iron laminations. These inefficiencies shorten battery life, increase operating temperature, and reduce overall system reliability.

The brushless coreless motor addresses these challenges directly. By eliminating the iron core, it significantly reduces magnetic and electrical losses. The lightweight, self-supporting coil structure minimizes resistance and allows heat to dissipate more effectively, resulting in:

Higher Electrical Efficiency: More of the input power is converted into useful mechanical motion instead of wasted as heat.

Lower Power Loss: Reduced resistance and the absence of iron laminations mean lower I²R and core losses.

Extended Battery Runtime: Devices powered by coreless dc motors or brushless coreless motors can operate longer on a single charge, which is crucial for portable systems.

This efficiency advantage translates into real-world benefits across multiple industries:

Portable Drills and Power Tools: Workers can operate for longer periods without frequent recharging, improving productivity.

Drones and UAVs: High speed coreless motors extend flight time, a critical factor in both recreational and industrial drone applications.

Wearable Devices: Medical pumps, smart health devices, and compact electronics rely on low power consumption to remain lightweight and reliable.

Sustainability-Oriented Designs: For companies aiming to reduce carbon footprint, the efficiency of coreless motors directly supports greener, more sustainable product development.

In an era where energy efficiency is both an engineering goal and an environmental responsibility, the brushless coreless motor stands out as an enabling technology. It not only saves power but also enhances performance, making it essential for next-generation devices that depend on compact, long-lasting energy solutions.

7. Compact Size with High Power Output

One of the defining strengths of the coreless motor is its exceptional power-to-size ratio. Thanks to its lightweight, self-supporting coil structure, the motor can deliver higher torque and output power within a smaller footprint compared to traditional iron-core designs. This results in higher torque density, which allows engineers to achieve powerful performance without compromising on size or weight.

In many cases, a high speed coreless motor that fits in the palm of your hand is capable of driving an entire drone or precision device with remarkable efficiency. The ability to concentrate power in such a compact form factor opens the door to countless design possibilities, especially in industries where space and weight are critical.

Key advantages of compact, high-output design include:

Optimized Space Utilization: Engineers can fit motors into devices with strict dimensional constraints without reducing performance.

Miniaturization of Systems: Products can be made smaller, lighter, and more portable, meeting modern consumer and industrial demands.

High Performance in Small Devices: Even miniature actuators powered by coreless dc motors can deliver consistent torque and speed.

Real-world applications demonstrate this capability clearly:

Miniature Drones: A high speed coreless motor weighing only a few grams can lift the drone body, battery, and camera, proving its unmatched power density.

Medical Devices: Compact surgical drills or handheld diagnostic tools require strong output in confined spaces.

Robotics and Automation: Small robotic grippers and actuators powered by brushless coreless motors achieve reliable movement in environments where every millimeter matters.

By combining compact design with robust power delivery, the coreless motor empowers engineers to push the limits of product innovation. From drones and medical instruments to next-generation robotics, this balance of size and output is what makes coreless technology so attractive across diverse industries.

8. Precision Control in Robotics

Precision is the cornerstone of modern robotics. Every robotic joint, servo, or actuator demands accurate, repeatable motion to perform tasks reliably, from assembly lines to surgical procedures. Traditional motors, with their higher inertia and cogging torque, often struggle to deliver the level of control required in these demanding applications.

A coreless dc motor addresses these challenges perfectly. Its linear torque response and fast reaction times enable micrometer-level adjustments and smooth motion control. Engineers can design robotic systems that respond instantly to input signals, maintain precise trajectories, and repeat complex movements with consistent accuracy.

Key advantages in robotic applications include:

Smooth and Repeatable Motion: Low inertia and minimal cogging allow for fluid joint movement, critical in pick-and-place robots and collaborative robotic arms.

Micrometer-Level Positioning: Surgical robots rely on coreless motors to execute highly precise incisions or manipulations, where even a small deviation could impact patient safety.

Fast Dynamic Response: In humanoid robotics and autonomous manipulators, coreless motors ensure limbs and end-effectors react quickly to environmental changes.

Real-world applications highlight their value:

Surgical Robots: Brushless coreless motors provide steady, precise control in robotic-assisted surgeries.

Industrial Automation: Pick-and-place machines achieve high-speed operation without sacrificing accuracy.

Humanoid Robotics: Coreless motors allow for natural, fluid movements that mimic human motion, enhancing performance in interactive or service robots.

By combining low inertia, smooth torque output, and rapid responsiveness, coreless dc motors and brushless coreless motors empower engineers to build robots that perform complex, delicate, and high-speed tasks reliably. This precision makes them an essential component in cutting-edge robotic systems.

9. Reliability in Harsh Environments

Many industrial and aerospace applications operate under extreme conditions where mechanical robustness and electrical reliability are non-negotiable. Traditional iron-core motors often face challenges in such environments: vibrations, shocks, and temperature fluctuations can cause mechanical wear, loss of precision, and even premature failure.

Brushless coreless motors are uniquely suited to these conditions. Their lightweight rotor windings reduce mechanical stress on moving parts, while the absence of an iron core minimizes magnetic losses and heat generation. This combination results in motors that are more resilient, durable, and reliable under harsh operational conditions.

Key reliability advantages include:

Vibration and Shock Resistance: Lightweight construction reduces inertial stress, making these motors ideal for high-vibration environments.

Thermal Stability: Efficient heat dissipation allows consistent performance even in extreme temperature ranges.

Longevity: Reduced wear on mechanical components extends the motor’s service life, lowering maintenance requirements and downtime.

Industries that benefit from these properties include:

Aerospace: Satellite deployment mechanisms, attitude control actuators, and space robotics rely on brushless coreless motors because failure is not an option in orbit.

Defense and Military Robotics: Unmanned vehicles, drones, and portable field equipment demand motors that maintain performance under shock, dust, and temperature extremes.

Industrial Automation: High-speed production lines and precision machinery benefit from motors that can sustain repeated operations without degradation.

By combining robustness, reliability, and efficiency, brushless coreless motors provide engineers with a dependable solution for applications where failure is unacceptable. Their ability to perform consistently under harsh conditions makes them indispensable in aerospace, defense, and industrial automation.

10. Versatility Across Industries

Few motor technologies demonstrate as much cross-industry adaptability as the coreless motor. Its combination of compact size, high efficiency, low inertia, and smooth torque output makes it ideal for a wide range of applications, from pocket-sized consumer devices to critical aerospace systems.

Key industry applications include:

Medical Devices: Coreless motors power surgical drills, dental handpieces, and infusion pumps, where precision, reliability, and low weight are crucial. Their smooth operation ensures patient safety and operator comfort during extended procedures.

Consumer Electronics: Compact coreless dc motors and brushless coreless motors drive devices like electric shavers, handheld gimbals, and digital cameras. Low noise, high responsiveness, and long battery life enhance user experience.

Aerospace: In satellites, drones, and space robotics, brushless coreless motors serve as actuators, gyroscope stabilizers, and propulsion components. Their lightweight, high-power-density design is critical for minimizing payload and maximizing efficiency in weight-sensitive applications.

Automotive: Coreless motors are increasingly used in advanced driver-assistance actuators, small pumps, and precision control systems, where compact design, rapid response, and durability under vibration are essential.

The versatility of coreless motors lies in their ability to adapt to the specific demands of each sector without sacrificing performance. Engineers benefit from a single motor technology that can meet stringent requirements across multiple applications, streamlining design and reducing the need for specialized solutions.

From micro-scale gadgets to high-stakes aerospace equipment, coreless dc motors and brushless coreless motors consistently demonstrate their adaptability, proving that this technology is not just innovative—it is universally practical.

11. Coreless DC Motor vs. Brushless Coreless Motor

Although both belong to the coreless motor family, the coreless dc motor and the brushless coreless motor differ significantly in how they operate and where they are best applied. Understanding these differences helps engineers choose the right solution for their specific needs.

Coreless DC Motor

A coreless dc motor relies on traditional brushed commutation. This makes it simple, cost-effective, and compact, with the ability to deliver high torque in short bursts. Because of its straightforward design, it is widely used in toys, small pumps, handheld medical tools, and portable electronics. However, the use of brushes means there is mechanical wear, limiting its lifespan and making it less ideal for continuous-duty applications.

Brushless Coreless Motor

A brushless coreless motor, by contrast, eliminates brushes entirely and instead uses electronic commutation. This greatly improves efficiency, durability, and reliability, enabling continuous operation with minimal maintenance. These qualities make it the preferred choice in aerospace systems, surgical robots, industrial automation, and drones, where uptime and performance are critical. While typically more expensive, the longer lifespan and reduced maintenance offset the higher upfront cost.

|

Feature |

Coreless DC Motor |

Brushless Coreless Motor |

|---|---|---|

|

Commutation |

Mechanical (brushes) | Electronic (sensor/sensorless) |

|

Efficiency |

Moderate | High |

|

Lifespan |

Limited by brush wear | Very long, minimal wear |

|

Cost |

Lower | Higher upfront, lower lifecycle cost |

|

Best Use Case |

Toys, small pumps, handheld devices | Aerospace, medical, robotics, drones |

|

Duty Cycle |

Short bursts | Continuous operation |

Both technologies highlight the flexibility of coreless motor design. If cost and simplicity are the priorities, the coreless dc motor is an excellent choice. When continuous duty, efficiency, and long service life are essential, the brushless coreless motor is the superior option. Together, they provide engineers with a spectrum of choices tailored to application-specific requirements.

12. Future Trends in High Speed Coreless Motor Development

Advanced Materials and Alloys

Future coreless motor designs are increasingly experimenting with nanomaterials, advanced copper alloys, and lightweight composites. By reducing electrical resistance and enhancing thermal conductivity, these materials allow higher RPM ranges with less energy loss. For brushless coreless motors, this means improved efficiency in continuous-duty applications such as aerospace actuators and industrial automation.

Miniaturization with More Power

One of the strongest trends is miniaturization. Engineers are already producing coreless dc motors smaller than a coin that still deliver impressive torque-to-weight ratios. As designs shrink further, expect wearable medical devices, IoT sensors, and even smart textiles to integrate high-performance motion systems that were once only possible in large industrial machines.

Integration into Smart and Autonomous Devices

The rise of IoT, autonomous vehicles, and robotics is creating new demand for compact and reliable motion control. High speed coreless motors are particularly well-suited because they offer fast response, smooth control, and long service life. We are likely to see them embedded in:

Wearables (haptic feedback systems, health monitoring tools)

Smart tools (precision drills, portable robotics kits)

Next-generation robotics (micro-robots for inspection, surgical nano-bots, warehouse automation units)

Sustainability and Energy Efficiency

Future designs will also focus on eco-efficiency. By combining brushless coreless motor architectures with renewable energy storage systems, manufacturers will reduce environmental impact while extending device lifespan. This is particularly relevant for drones, electric mobility solutions, and portable medical systems, where sustainability is becoming a top design requirement.

13. Cost Efficiency Over the Long Run

At first glance, a coreless dc motor or brushless coreless motor may appear to be a more expensive investment compared to traditional iron-core designs. The upfront price tag is indeed higher. But when analyzed over the full product life cycle, the economic advantage of coreless technology becomes clear.

Lower Maintenance and Fewer Replacements

Brushed coreless dc motors typically have a longer service life than cored brushed motors because their lightweight windings place less mechanical stress on the system. In the case of brushless coreless motors, the benefit is even greater: with no brushes to wear out, routine maintenance is minimized, and replacements are needed far less often. This reduction in consumable parts directly lowers operating costs.

Reduced Downtime and Higher Productivity

In industries where every second of downtime matters—such as manufacturing, healthcare, or aerospace—the reliability of coreless motors pays for itself. Fewer failures mean fewer interruptions, allowing production lines to keep moving and surgical teams to continue working without equipment failures. Over time, this translates to measurable financial savings.

Energy Savings Add Up

Both coreless dc motors and brushless coreless motors operate more efficiently, converting more electrical power into usable motion. Even a small percentage of energy savings per unit becomes significant when scaled across fleets of devices or equipment running 24/7. For businesses conscious of both energy costs and sustainability goals, this efficiency makes coreless technology a smart long-term choice.

A Better Return on Investment (ROI)

When factoring in purchase price, operating efficiency, maintenance costs, and service life, the total cost of ownership (TCO) of a coreless motor is often significantly lower than that of a traditional iron-core alternative. For companies evaluating high-performance solutions, the ROI is not only financial but also operational—delivering reliability and performance that helps products succeed in competitive markets.

14. Quiet Operation Benefits

Smooth, Silent Performance

Because coreless dc motors eliminate the iron core, they also eliminate cogging torque and harsh commutation effects that generate vibration and noise. The result is exceptionally smooth and quiet operation, even at high rotational speeds.

Critical in Medical and Scientific Applications

In hospitals and laboratories, silence is not just a preference but a necessity. Surgical equipment, diagnostic tools, and precision lab instruments often rely on brushless coreless motors for their ability to run nearly silently. This ensures both patient comfort and an environment free from distracting or harmful noise levels.

Enhanced Consumer Experience

From hearing aids to premium cameras, handheld gimbals, and luxury personal care products, customers expect technology to perform powerfully without drawing attention to itself. A high speed coreless motor can deliver exceptional performance while remaining virtually noiseless—a feature that becomes a selling point in competitive consumer markets.

Productivity and Comfort in Work Environments

Quiet operation is not just about comfort; it can also improve productivity. Factory robots, office equipment, and smart home devices equipped with coreless dc motors contribute to a quieter workspace, reducing stress and fatigue for operators and users alike.

15. Why Engineers and Designers Prefer Coreless Motors

Lighter, Yet More Powerful

In applications where every gram matters—whether in a surgical handpiece, a drone propulsion system, or a satellite actuator—the lightweight architecture of coreless motors enables engineers to reduce system mass without sacrificing power or torque.

Efficiency That Drives Sustainability

Modern industries demand technologies that are not only effective but also sustainable. By wasting less energy as heat, coreless motors extend battery life in portable devices, cut energy consumption in industrial systems, and contribute to greener, more responsible product design.

Reliability Engineers Can Trust

From aerospace to robotics, reliability is mission-critical. Brushless coreless motors excel in durability and consistency, operating smoothly in environments where vibration, shock, or extreme temperatures could cripple a conventional motor. This reliability is one of the key reasons engineers specify coreless designs in high-stakes applications.

A Platform for Innovation

Perhaps most importantly, coreless motor technology empowers innovation. Whether the goal is to miniaturize medical tools, increase drone flight efficiency, or enhance user experience in consumer electronics, engineers and designers recognize that coreless motors open doors to possibilities that iron-core motors limit.

Frequently Asked Questions (FAQ)

Q1: What is a coreless motor?

A coreless motor eliminates the iron core inside the rotor, making it lighter, more efficient, and faster in response compared to traditional motors.

Q2: What's the difference between a coreless dc motor and a brushless coreless motor?

A coreless dc motor uses brushes for commutation and is ideal for compact, low-cost devices. A brushless coreless motor uses electronic commutation, offering higher efficiency, longer life, and smoother performance.

Q3: Why choose a high speed coreless motor?

High speed coreless motors can run at tens of thousands of RPM while staying cool and stable, making them perfect for drones, robotics, and precision medical tools.

Q4: Are coreless motors more expensive?

Yes, but their durability, energy efficiency, and low maintenance often make them more cost-effective in the long run.

Key words:

Recent News