01

2025

-

09

Why the Next 10 Years of 12v Worm Gear Motors Will Smash the Last 10

Key words:

Discover why 12v worm gear motors are set to outperform the last decade with higher torque, smart control, and efficiency.

Author:

KESHUO

Table of Contents

- The Core Design – Why Worm Gear Systems Stand Out

- Lessons from the Last Decade

- Why High Torque Matters More Than Ever

- Expanding Applications Across Industries

- What Will Drive the Next 10 Years of Growth

- Customization and Innovation

- Comparison with Other Motor Technologies

- Why the Future Belongs to 12v Worm Gear Motors

- FAQ

Over the last decade, 12v worm gear motors have undergone steady enhancements in efficiency and accessibility. Their self-locking mechanism, which prevents reverse motion under load, has made them indispensable in applications demanding stability and safety. As industries increasingly adopt automation, sustainability, and smart technologies, the next ten years are projected to witness accelerated innovation. Experts foresee a significant expansion in the use of 12v worm drive motors driven by advancements in materials, IoT integration, and superior energy efficiency.

The Core Design – Why Worm Gear Systems Stand Out

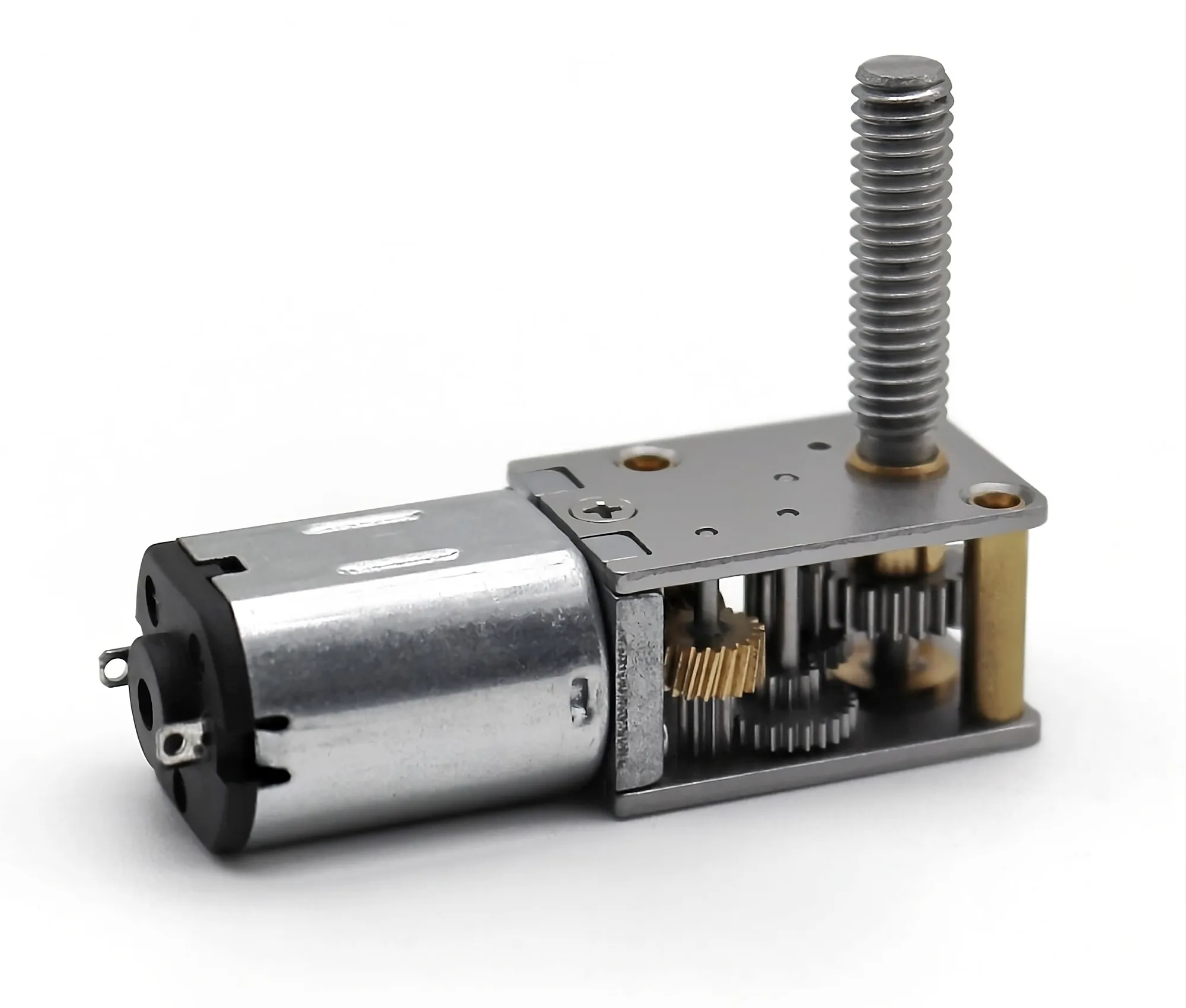

At the heart of every 12v worm gear motor lies a simple yet highly effective mechanism: the worm and gear. The worm, a screw-like shaft, meshes with the gear at a right angle, converting rotational motion into controlled torque. This configuration creates a very high reduction ratio in a compact space, which is difficult to achieve with spur or helical gears. While spur gears transfer motion parallel to their shafts and helical gears offer smoother engagement, neither can match the unique torque density and space-saving characteristics of a 12v DC worm gear motor.

One of the most valuable features of worm gearing is its natural self-locking function. Because of the steep angle and friction between the worm and gear teeth, the system resists reverse motion. This means that when power is cut, the output shaft holds its position without the need for additional brakes. In vertical or safety-critical systems, such as hospital beds, wheelchair lifts, or industrial hoists, this property is invaluable. Engineers who design automation equipment know that the ability to prevent back-driving ensures both safety and energy savings.

It is this combination of mechanical simplicity, safety, and reliability that explains why engineers around the world continue to rely on worm gear DC motor 12v solutions. As industries demand smarter, smaller, and safer systems, the distinctive characteristics of 12v worm gear motors ensure that they will remain a popular choice in compact motion control for years to come.

|

Model: GM1812-N20 Motor Types: Worm Gear Motor Voltage: 12V DC Worm Gear Ratio: 42/80/105/121/158/230/302/346/453 Rated Torque: 0.05kgf·cm ~ 0.45kgf·cm ≈ 0.45N·cm ~ 4.4N·cm ≈ 0.69ozf·in ~ 6.24ozf·in |

|

Model: GM3246-370CA Motor Types: 12V Worm Gear 370 Motor Voltage: 12V DC No-Load Speed: 7900rpm Worm Gear Ratio: 37.3/150/250/324/600/972/1700/2900 Rated Torque: 0.73kgf·cm ~ 10.0kgf·cm ≈ 7.0N·cm ~ 98.0N·cm ≈ 10.1ozf·in ~ 138.8ozf·in |

|

Lessons from the Last Decade

Over the past ten years, the worm gear DC motor 12v found steady use in automotive systems such as seat adjusters and window mechanisms, as well as in small automation projects. These motors offered reliable torque and low-voltage operation, making them a practical choice for many engineers.

Still, earlier designs had some drawbacks. Efficiency was only moderate due to friction losses, housings were often bulkier than desired, and service life could be limited under continuous load.

Recent advances have solved many of these issues. The use of light alloys, high-strength plastics, and better lubricants has made 12v worm gear motors lighter, more efficient, and more durable. At the same time, pairing them with electronic speed controllers has given engineers finer control over speed and torque, expanding their role in robotics, smart devices, and automation.

These improvements mean that the 12v DC worm gear motor has moved from a basic component to a refined solution, ready to meet higher demands in the decade ahead.

Why High Torque Matters More Than Ever

In simple terms, torque is the twisting force that allows a motor to move heavy loads, especially at low speeds. For many applications, raw speed is less important than the ability to push, lift, or hold weight steadily. This is where the worm gear motor 12v high torque design stands out.

Real-world examples are easy to find. In RV slide-outs, these motors provide the muscle to extend and retract heavy panels smoothly. In solar tracking systems, they move panels slowly but with enough strength to maintain alignment all day long. On factory conveyor belts, the same principle ensures that goods move steadily without slippage.

Recent generations of 12v worm gear motors also offer higher torque density—delivering more torque per unit of size and weight. This means engineers can achieve stronger performance without sacrificing compactness, an essential factor for mobile equipment and robotics.

The combination of high torque with a low 12-volt input is especially valuable in battery-powered systems. A 12v DC worm gear motor can run efficiently from portable power sources while still providing the strength needed for demanding mechanical tasks. This balance of power and efficiency explains why high torque is more critical today than ever before.

Expanding Applications Across Industries

The versatility of the 12v DC worm gear motor has made it a reliable choice across a wide range of industries.

Automotive: These motors power seat lifts, windshield wipers, and RV or trailer systems, where smooth movement and high torque are essential for comfort and safety.

Home and Office Equipment: From adjustable desks to smart blinds and automated windows, the 12v worm gear motor provides compact power in devices designed for convenience and modern living.

Medical Devices: In hospital beds, mobility scooters, and dental chairs, stability and reliability matter as much as strength, making the worm gear DC motor 12v a natural fit.

Agriculture: Lightweight feeders, sprayers, and compact tools often rely on low-voltage motors to handle demanding tasks in rugged environments.

Renewable Energy: Precision solar tracking and adjustable wind equipment use 12v worm drive motors to move panels steadily while resisting back-driving in strong winds.

Robotics: Automated guided vehicles (AGVs), service robots, and warehouse systems benefit from the durability and compact size of worm gear motor 12v high torque units.

In every case, the advantages of durability, compactness, and cost-effectiveness explain why industries continue to adopt these motors. The ability to deliver strong performance in a small package ensures that the 12v worm gear motor will remain a popular choice for both traditional and emerging applications.

|

Model: GM1812-050 Motor Types: DC Worm Gear 050 Motor Voltage: 12V DC Motor No-Load Speed: 17000rpm Worm Gear Ratio: 21/42/79/118/236/302/603/1030 Rated Torque: 252gf·cm ~ 12360gf·cm ≈ 2.47N·cm ~ 121.2N·cm ≈ 3.49ozf·in ~ 171.68ozf·in |

What Will Drive the Next 10 Years of Growth

Several major trends are set to accelerate the adoption of 12v worm gear motors in the coming decade. The rise of robotics and smart automation in both industry and daily life will create new demand for compact, reliable drive systems. At the same time, the global push toward renewable energy and energy-efficient solutions will highlight the value of 12v worm drive motors, which operate effectively at low voltage and deliver strong torque for solar tracking and similar applications.

Another driver of growth is miniaturization. As motors become smaller while maintaining torque density, it is easier to integrate them with sensors for real-time feedback and precision control. This makes the modern worm gear DC motor 12v more adaptable to complex automation tasks.

On the consumer side, DIY and maker communities are increasingly adopting these motors. As 12v worm gear motors become easier to source and customize, they are finding roles in hobby robotics, home projects, and small-scale automation. Finally, the rise of AI-driven predictive maintenance will allow businesses managing large fleets of equipment to monitor performance and prevent failures, ensuring smarter deployment of worm gear motor 12v high torque models in the field.

Together, these forces point to a decade of stronger demand, wider applications, and continuous innovation.

Customization and Innovation

One reason the 12v worm gear motor continues to gain popularity is the growing level of customization offered by manufacturers. Companies such as Keshuo are now able to provide motors with tailored gear ratios and torque levels, ensuring that each worm gear DC motor 12v matches the specific needs of a customer’s application. This flexibility allows engineers to design systems that balance speed, power, and efficiency without compromise.

Another major step forward is the integration of sensors and controllers directly into 12v worm gear motors. Built-in feedback systems give real-time data on speed, torque, and load, which improves precision and reliability. For industries like medical equipment or automation, this integration reduces the need for external hardware and makes setup much simpler.

There are also new opportunities in modular motor systems. Robotics startups, in particular, benefit from compact modules that can be quickly adapted or swapped depending on the project. By using worm gear motor 12v high torque modules with standardized connections, developers can speed up prototyping and bring innovative products to market faster.

Comparison with Other Motor Technologies

When choosing a drive solution, engineers often compare the 12v worm gear motor with other motor types. Spur gear motors, for example, are efficient and cost-effective, but they lack the self-locking function and torque density that a worm gear DC motor 12v provides. This makes spur gears less suitable for vertical loads or applications that require holding power without continuous energy consumption.

Stepper motors, on the other hand, are known for their precision and control, making them excellent for positioning tasks. However, they are not ideal when high torque at low speeds is required. Unlike a worm gear motor 12v high torque, stepper motors can struggle with heavy loads and may require additional components to prevent back-driving.

|

Motor Types: Worm Gear Stepper Motor Voltage: 12V DC Phases: 2-Phases Worm Gear Ratio: 42/63/80/105/121/230/242/302/346/453/692 Rated Torque: 0.580kgf·cm ~ 7.958gf·cm ≈ 5.68N·cm ~ 78.04N·cm ≈ 8.05ozf·in ~ 110.51ozf·in |

Why the Future Belongs to 12v Worm Gear Motors

After years of steady use in sectors ranging from automotive to robotics, the 12v worm gear motor has proven itself as more than just a convenient option. Its consistent ability to deliver torque, withstand demanding duty cycles, and adapt to diverse system requirements shows why it has earned long-term trust in the market. As engineers with experience know, reliability and practicality often outweigh the chase for novelty, and the 12v DC worm gear motor continues to meet those fundamental needs.

The future will not be without competition from other technologies, but incremental advances in materials, lubrication, and integrated electronics are already reshaping how worm gear motor 12v high torque models perform. These improvements suggest a measured but meaningful shift: broader adoption in renewable energy, robotics, and compact automation is likely, without ignoring the strengths of alternative solutions.

Keshuo Motor has been part of this journey, supporting projects that demand both off-the-shelf reliability and tailored performance. For organizations planning their next generation of equipment, evaluating modern 12v worm drive motors is less about chasing trends and more about recognizing a proven technology evolving with the times. With the right design choices, the worm gear DC motor 12v can continue to serve as a dependable partner in the decade ahead.

Key words:

Recent News