Founded in 2012

Factory Area

Exporting Country

24 Patent R&D Certificate

More Than 400 Customers Served

about Us

Motor Micro

Shenzhen Keshuo Motor Co., Ltd. (Abbreviation: Keshuo Motor) was founded in 2012 and is proudly based in Shenzhen, China. As a professional Stepper Motor Manufacturer and DC Motor Supplier, we focus on high-precision Micro Drive System solutions.

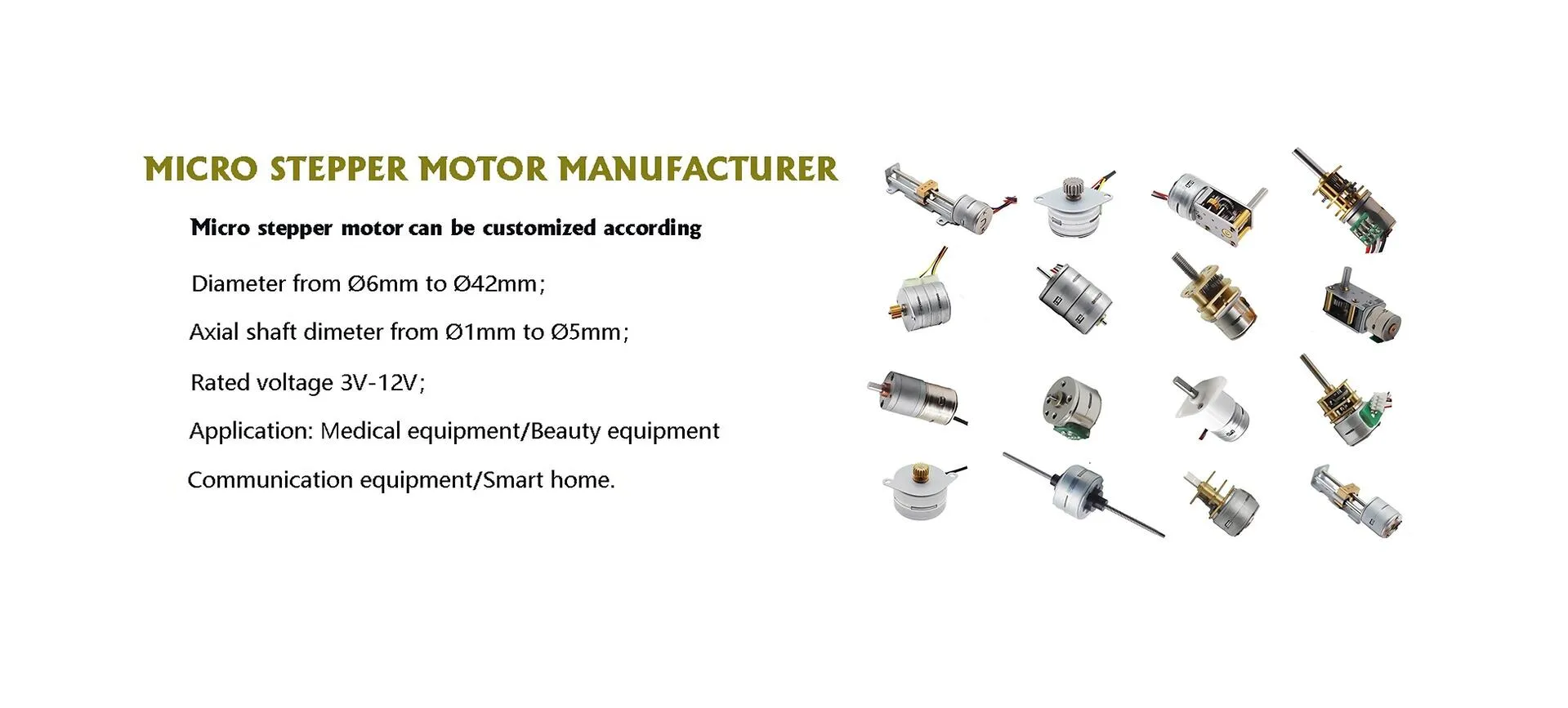

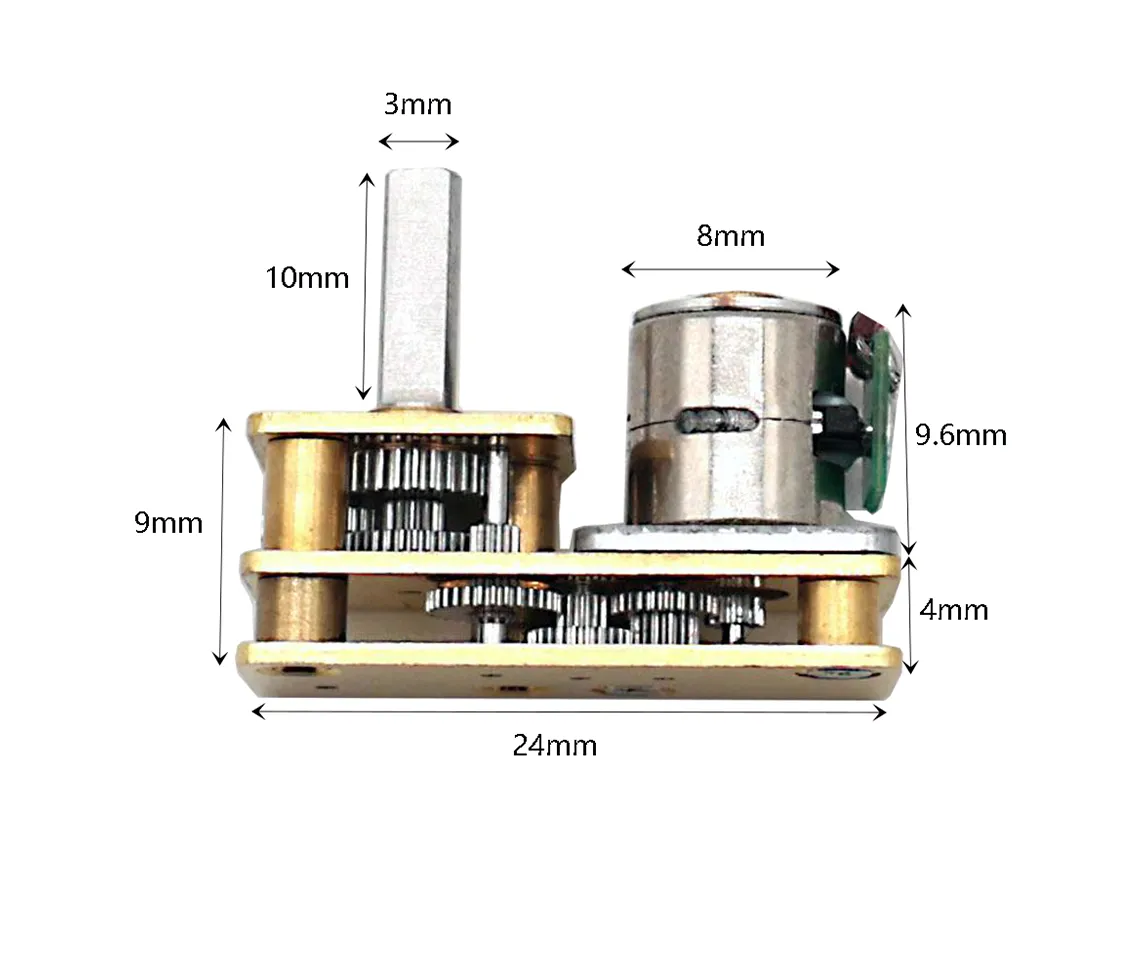

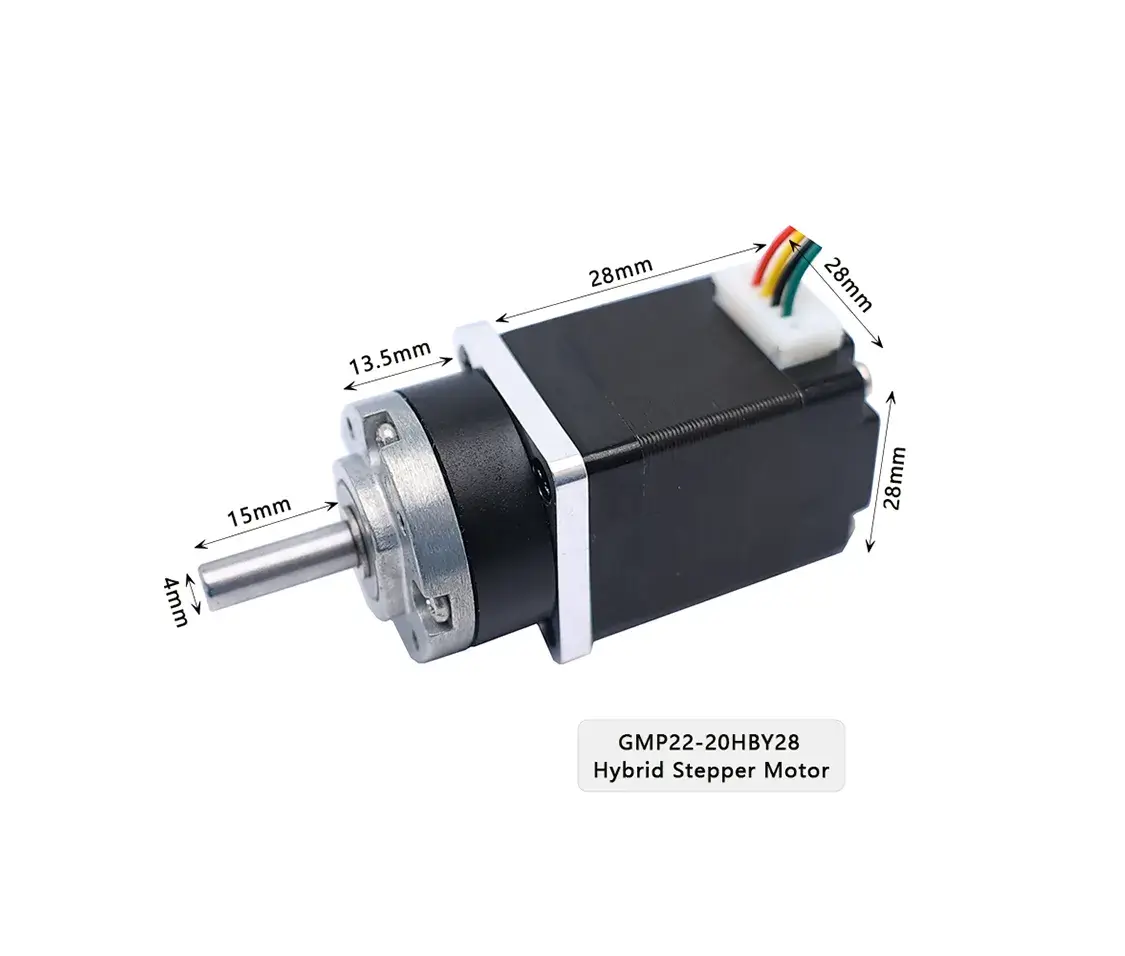

Our core product range includes precision

Brushed DC Motor, Stepper Motor, Hybrid Stepper Motor (NEMA Stepper Motor), Planetary Gear Motor, and Brushless DC Motor (BLDC). These motors are trusted across diverse industries, including Medical Testing and Analysis, Security Systems, 5G Technology, Automotive, Communications, Iris Recognition, AI, Smart Homes, Smart Locks and Switches, Wearable Devices, Robotics, Power Tools, Beauty Devices, and more.

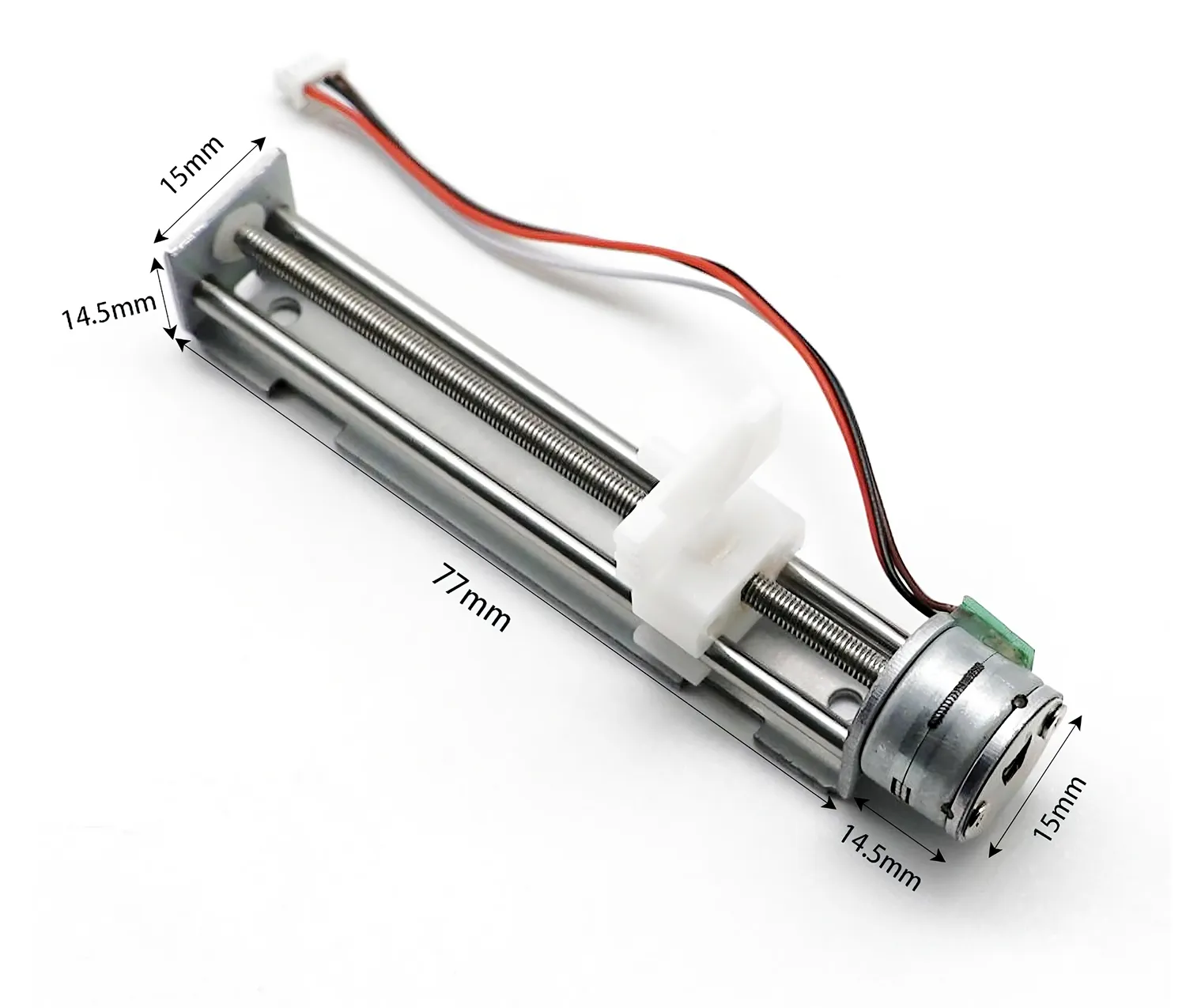

Each product is carefully engineered to deliver exceptional performance while maintaining optimal size and weight. Alongside our motors, we also provide precision Gearboxes (e.g., Planetary Gearbox or Worm Gearbox), Encoders (Magnetic Encoder or Optical Encoder), and Linear Components (Lead Screw, Linear Slider)—offering our customers complete, high quality Motion Solutions.

Product Center

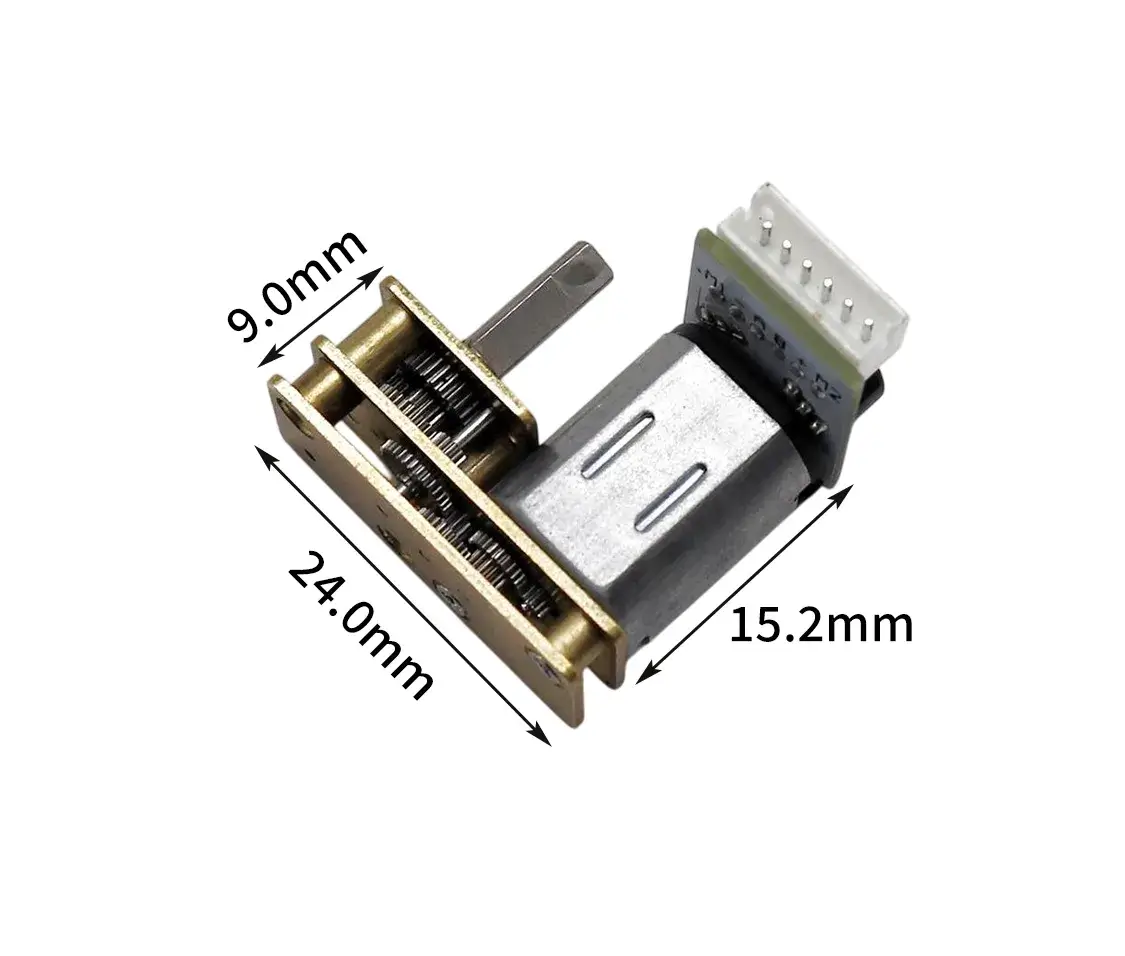

Small Stepper Motor

Why Keshuo is Trusted by 400+ Clients

High Precision, Low Noise

Long lifespan, high performance

Exquisite appearance sturdy and durable structure

Small size, powerful

Multiple Processing Techniques

Dry running, reliable

Application industry

Medical Equipment

01

Medical Equipment

Medical Equipment

Surgical robots, microscopes, syringes, infusion pumps, CT scanners, X-ray machines, nuclear magnetic resonance imaging machines, artificial heart valves, artificial limbs, etc. These devices need high-precision position control and speed regulation to achieve accurate operation and treatment.

Industrial Automation

02

Industrial Automation

Industrial Automation

Conveyor belt systems, assembly line equipment, cutting tools for machining, milling, drilling, packaging machinery, automated testing equipment, food and beverage processing, automated warehousing systems, printing and manufacturing equipment, mining and construction equipment. In addition, they can also be applied to audio and video equipment, office automation equipment, computer peripherals, and other products.

Smart Home

03

Smart Home

Smart Home

Smart curtains. Smart lighting: Dimming lights and moving head light. Smart security: Surveillance cameras and door sensors. Smart environment control: Air purifiers, air conditioning and other equipment's air intake. The application of micro motors in smart homes can enhance convenience, comfort, and security of household life.

Precision Instrument

04

Precision Instrument

Precision Instrument

Optical instruments: Telescopes, microscopes, and other optical instruments. Electron microscopes: Tunneling microscopes, atomic force microscopes, and other electron microscopes. Laser device. The application of micro motors in precision instruments can enhance accuracy, convenience, and reliability in laboratory work.

Beauty Equipment

05

Beauty Equipment

Beauty Equipment

Eyebrow Trimmers, Facial Cleansing Brushes, Nail Care Devices, Skin Care Devices, Hair Styling Tools, Mascara Applicators, Massaging Devices, Hair Removal Devices, Electric Shavers Advantage: Micro-motors in beauty products offer precision, efficiency, and compact design, enhancing user experience through targeted and effective applications.

Automobile

06

Automobile

Automobile

Power Windows and Door Locks, Seat Adjustments, Steering Column Adjustments, Fuel Injection Systems, Side Mirror Adjustments, Climate Control Systems, Hybrid and Electric Vehicles, Electric Power Steering car tailgate Advantage: Micro-motors in the automotive industry provide seamless and precise functionality, contributing to enhanced vehicle safety, comfort, and overall performance.

echnical advantages and excellent product quality advantages

Having strong technical strength, professional, focused, efficient and advanced production facilities, 20 years of rich experience in excellent product quality, advanced testing methods, high-purity oxygen free copper, and excellent conductivity; Selected high-quality insulation materials are safe and environmentally friendly.

Having the advantage of specialization to meet customers' needs of continuously improving product levels, reducing energy consumption, facilitating production, and improving efficiency.

Industry Qualification

Brushless DC Motor

Customized Reliable Exclusive Motor Solutions

Selected High Quality Materials

CNC Machining Process

Protection Grade Requirements

Operating Environment Requirements

Various Motor Specifications

Stable Delivery Capability

news

Enquire Now

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!