28

2025

-

08

High Torque Small Motor Selection Guide: Tips for Picking the Perfect Power Core

Key words:

Discover how to choose the best High Torque Small Motor for robotics, medical, and industrial use with efficiency and reliability.

Author:

KESHUO

Table of Contents

- 1. Understanding the Concept of High Torque in Small Motors

- 2. Categories of Small High Torque Motors

- 3. Key Parameters When Selecting a High Torque Small Motor

- 4. Applications of High Torque Small Motors

- 5. Challenges in High Torque Small Motor Design

- 6. How to Choose the Perfect Small DC Motor High Torque Model

- 7. Practical Tips for Optimizing Motor Performance

- Conclusion

- Frequently Asked Questions (FAQ)

In today’s technology-driven world, industries demand machines and devices that are not only compact but also powerful enough to perform demanding tasks with precision. From robotics to automation, from consumer gadgets to medical equipment, engineers are constantly seeking motion solutions that deliver high torque without taking up much space. This is where the high torque small motor becomes an essential component.

This guide explores everything you need to know about high torque small motors—covering the basics of torque, different motor categories, critical selection parameters, and real-world applications. It also offers practical tips to help you choose the perfect motor for your project, while highlighting performance optimization strategies that can extend lifespan and enhance efficiency. By the end, you will have a clear roadmap for identifying the best power core to match your unique needs.

1. Understanding the Concept of High Torque in Small Motors

When engineers or designers discuss motors, two of the most important characteristics are speed and torque. Torque is essentially the rotational force that a motor produces. To put it simply, imagine tightening a screw with a screwdriver: the harder you twist, the greater the torque. In motor terms, torque is the ability to generate rotational movement against resistance.

Torque vs. Speed in Motor Design

Motors can be broadly divided into two categories:

Speed-oriented motors are designed to rotate very quickly but may lack the strength to move heavy loads. They are ideal for fans, pumps, or applications where velocity matters more than pulling power.

|

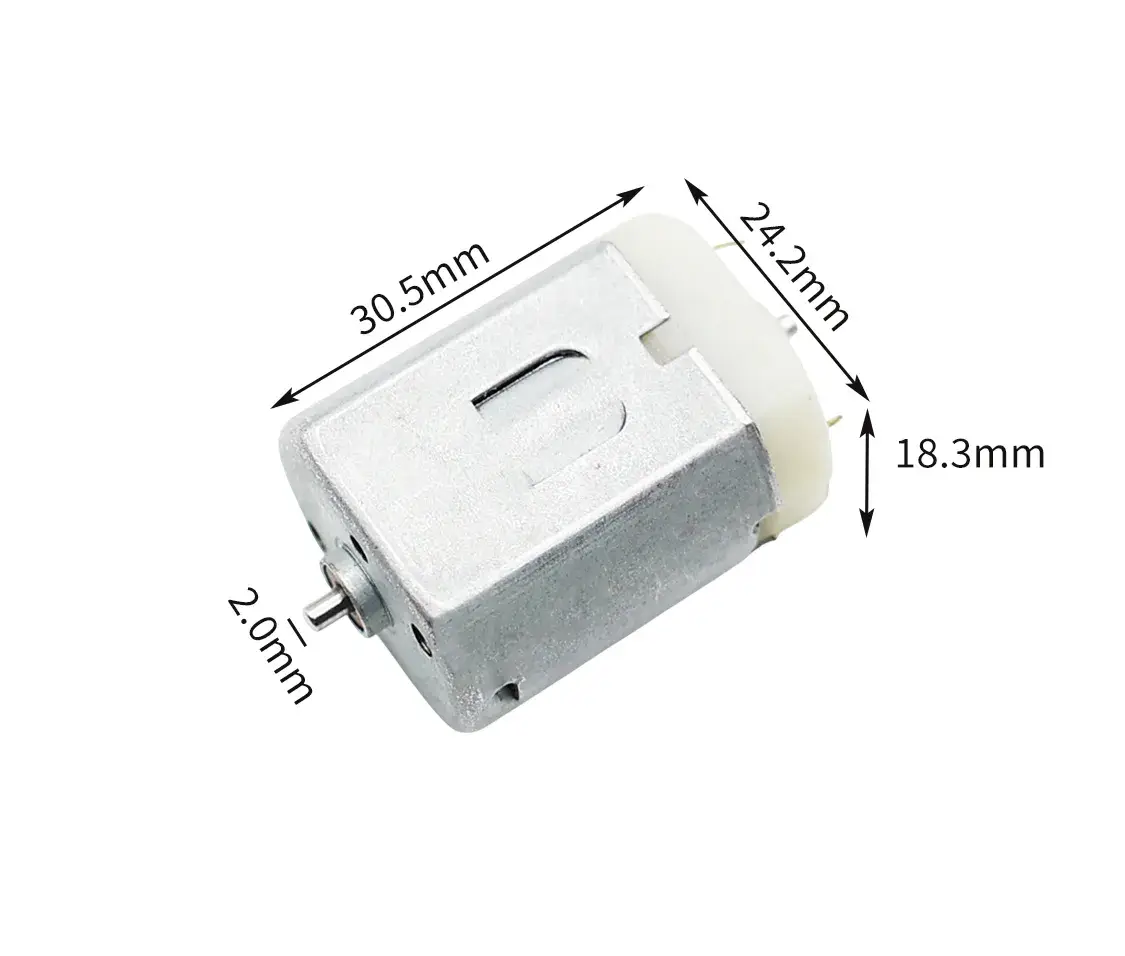

Motor Dimensions: 24.2mm*30.5mm*18.3mm Voltage: 12V DC No-load Speed: 10300rpm No-load Current: 61mA Rated Torque: 20g·cm Power: 2.9W Stall Torque: 206g·cm |

Torque-oriented motors, by contrast, prioritize strength over speed. A High Torque Small Motor is a perfect example—while it may not spin as rapidly as a high-speed motor, it is capable of handling demanding tasks like lifting, pushing, or overcoming mechanical resistance.

|

Model: 42HB480S4-300 Phase Count: 2-Phase |

This trade-off between speed and torque is illustrated in what engineers call the speed-torque curve, which shows that as one increases, the other typically decreases. Choosing the right balance is vital for application success.

Why High Torque Matters in Compact Designs

In many modern applications, space is limited but performance expectations are high. Robots, medical devices, or compact consumer electronics cannot accommodate bulky motors. Instead, they rely on a small high torque electric motor to provide sufficient force in a compact footprint. For example, a robotic arm joint may not need to spin extremely fast, but it must generate enough torque to lift objects reliably without failure. Similarly, portable surgical instruments must deliver powerful yet precise motion while remaining lightweight and easy to handle.

High torque becomes especially important when a device needs to overcome inertia, hold a position firmly, or drive a mechanical system that resists movement. In such cases, torque is not just desirable—it is critical to proper functionality.

Working Principle of a Small High Torque Electric Motor

At its core, the operation of a small DC motor high torque design is based on electromagnetic interaction. When current flows through the motor’s winding, it creates a magnetic field. This field interacts with permanent magnets inside the motor housing, generating rotational force—torque. By optimizing coil design, magnet strength, and sometimes integrating gear reduction, engineers can maximize torque output even in miniature packages.

What makes the small high torque electric motor particularly valuable is its efficiency in converting electrical energy into rotational power within constrained dimensions. With innovations like high-density magnetic materials and advanced control electronics, today’s compact motors deliver torque levels that were once possible only in much larger machines.

2. Categories of Small High Torque Motors

Brushed DC Motors

The brushed DC motor is a classic and time-tested design. It has been used for decades in countless devices due to its simplicity and affordability. This type of motor works by using brushes and a commutator to switch current direction in the windings, generating rotation.

Advantages:

Straightforward control using simple DC voltage.

High starting torque, making it suitable for applications that require immediate strength.

Cost-effective and widely available in many sizes.

Limitations:

The brushes physically wear down over time, leading to reduced lifespan and higher maintenance.

Operation generates electrical noise and audible sound, which may not be acceptable in precision environments.

Lower efficiency compared to modern alternatives.

Brushed DC motors are still widely used in toys, low-cost appliances, and devices where strong startup torque and budget-friendly solutions outweigh longevity concerns.

Brushless DC Motors (BLDC)

The brushless DC motor (BLDC) is an advanced evolution of the traditional design. Instead of brushes, it uses electronic commutation, often controlled by microchips, to manage current switching.

Advantages:

Higher efficiency and energy savings compared to brushed motors.

Longer operational life due to the absence of mechanical brushes.

Excellent torque output despite compact size.

Quieter and smoother operation, ideal for sensitive environments.

Because of these advantages, BLDC motors have become the go-to small high torque electric motor choice for robotics, drones, cooling fans, and precision instruments. They deliver strong torque while remaining lightweight and reliable.

Stepper Motors

Stepper motors are unique because they divide a full rotation into precise steps. Instead of continuous spinning, they move incrementally, which allows for very accurate position control.

|

Model: 10BY2510-N Motor Dimension: 10.0mm x 10.2mm Step Angle: 18°/step Voltage: 5V DC Resistance /Phase: 10Ω Current /Phase: 630mA Detent Torque: 6g.cm Holding Torque: 20g.cm |

Key Features:

Provide holding torque, meaning they can maintain a fixed position even without continuous motion.

Excellent for tasks where precision is more important than speed.

Easy to integrate with digital control systems for exact movement programming.

Common Applications:

3D printers, where exact positioning of the print head is essential.

CNC machines for controlled cutting and shaping.

Laboratory and measurement instruments, where precise incremental adjustments are essential.

Gear Motors (DC Motors with Gear Reduction)

When a standard DC motor does not provide sufficient torque, adding a gear reduction system is an effective solution. A gear motor combines a compact motor with a gearbox to achieve higher torque output.

Benefits:

Significantly increases torque by trading off rotational speed.

Provides more consistent and controllable motion in load-bearing applications, with self-locking capability that helps maintain position when power is off.

Widely available in many configurations and ratios.

Common Uses:

Door lock actuators, where strong but slow rotational movement is needed.

Vending machines, which rely on controlled torque to dispense items.

Automotive accessories like seat adjustment systems.

Each of these categories plays a vital role in modern industry. The choice between brushed DC, BLDC, stepper, and gear motors depends on specific application needs—whether the priority is cost, efficiency, precision, or raw torque in limited space.

3. Key Parameters When Selecting a High Torque Small Motor

Rated Torque vs. Peak Torque

Torque specifications are often listed in two forms: rated torque and peak torque.

Rated torque refers to the continuous torque that a motor can safely deliver without overheating or suffering long-term damage.

Peak torque represents the short-duration torque a motor can produce, often during startup or sudden load changes.

While peak torque may sound attractive, it can only be sustained for a limited time. Relying on it for continuous operation risks exceeding the motor’s design limits, reducing lifespan, and increasing the chance of mechanical failure. For demanding tasks, engineers should size the small high torque electric motor with adequate safety margins, ensuring rated torque comfortably matches operational loads.

Speed-Torque Curve Analysis

Every motor follows a speed-torque curve, which illustrates the trade-off between rotational speed and torque output. In general, as speed increases, torque decreases.

Understanding this curve is critical when selecting a small DC motor high torque unit because it ensures that the motor performs efficiently within the application’s load range. For instance, if an instrument requires steady torque at low speeds, choosing a motor optimized for high-speed performance would be inefficient and potentially harmful to the device. Matching the load profile with the motor’s natural torque curve guarantees smoother operation and longer service life.

Voltage and Current Considerations

Torque output is directly tied to the electrical input, especially current. In small DC motor high torque designs, the demand for higher current is common, as more electrical energy is converted into rotational force.

However, this has two important implications:

Power supply compatibility: The available voltage and current limits of the system must match motor requirements.

Controller selection: Motor drivers and electronic controllers must be sized appropriately to handle higher current without overheating or tripping protection circuits.

If these considerations are overlooked, even the most advanced High Torque Small Motor may underperform due to inadequate power delivery.

Size, Weight, and Packaging

One of the most attractive features of a small high torque electric motor is its ability to deliver power in a compact footprint. However, size and torque capacity are always in tension: the smaller the motor, the more challenging it becomes to maintain high torque.

Designers must carefully balance footprint and performance. In medical devices, for example, ultra-compact motors are essential to keep equipment lightweight and ergonomic, while still generating enough torque for reliable function. Similarly, in portable instruments or handheld tools, every gram of weight matters.

Thermal Management

High torque operation inevitably produces heat, and in compact motor designs, heat dissipation becomes one of the biggest challenges. Excessive temperatures can degrade insulation, damage windings, or demagnetize permanent magnets.

Effective strategies include:

Heat sinks: Adding external components to absorb and spread heat.

Forced air cooling: Using small fans or airflow channels to improve ventilation.

Material optimization: Employing high-temperature insulation materials and thermally conductive housings.

By integrating proper thermal management, a small DC motor high torque model can operate safely under continuous load without risking damage or shortened lifespan.

In summary, careful evaluation of torque ratings, speed-torque characteristics, electrical requirements, physical dimensions, and thermal management ensures that the chosen High Torque Small Motor will meet the needs of the application reliably and efficiently.

4. Applications of High Torque Small Motors

Robotics and Automation

Modern robotics relies heavily on compact power solutions. Robotic joints, grippers, and actuators must perform precise movements while handling loads that demand significant torque. A small high torque electric motor provides the strength necessary for lifting, rotating, or stabilizing components without compromising accuracy.

Medical Devices

The healthcare industry is one of the largest users of High Torque Small Motors because medical devices require both reliability and safety. From infusion pumps that must push fluids at controlled rates, to powered surgical instruments demanding precise yet strong rotation, torque plays a central role.

Automotive and Mobility Solutions

Automotive design incorporates many compact motors, each serving specialized functions. Examples include:

Electric seat adjustments, where a small DC motor high torque drives movement smoothly under load.

Power window lifts, which need strong torque to overcome resistance while maintaining quiet operation.

EV battery cooling pumps, where reliable torque ensures consistent fluid flow in demanding environments.

Durability is key in automotive applications because motors must withstand vibration, temperature extremes, and long duty cycles. Choosing a High Torque Small Motor designed for rugged conditions ensures long-term reliability on the road.

Consumer Electronics and Appliances

Consumers often interact with small high torque electric motors without realizing it. Compact yet powerful motors drive familiar devices such as:

Cameras, where motorized zoom and focus mechanisms rely on smooth torque delivery.

Electric toothbrushes, which require both power and compactness.

Drones, where lightweight motors provide both thrust and control precision.

Handheld tools, where a small DC motor high torque allows for effective drilling or cutting in a portable form.

In consumer products, a balance between quiet operation and strong torque is critical. Users expect convenience without sacrificing comfort or battery efficiency.

Industrial Equipment

The industrial sector is another major beneficiary of High Torque Small Motors. Packaging machines, conveyor systems, and automated assembly lines all require reliable torque in continuous operation. These environments often demand high duty cycles and efficiency, where downtime translates directly into financial loss.

A small high torque electric motor ensures consistent power delivery, whether it’s driving rollers, actuating valves, or positioning components in precise sequences. With proper selection and thermal management, these motors can sustain performance even under the stress of nonstop industrial workloads.

In every field—from robotics to healthcare, automotive systems to industrial automation—the small DC motor high torque design proves its value by combining compactness with strength. Its applications continue to expand as engineers seek new ways to push performance while saving space.

5. Challenges in High Torque Small Motor Design

While the high torque small motor has become a cornerstone of modern engineering, its design and implementation are not without challenges. Engineers must overcome several technical and economic hurdles to ensure these compact power units deliver reliable performance across different industries.

Balancing Torque, Efficiency, and Heat Dissipation

Generating high torque in a small frame means higher electrical currents and stronger magnetic fields, both of which create heat. For a small high torque electric motor, managing this heat while maintaining efficiency is a constant struggle. Without adequate thermal control, excessive heat can reduce insulation life, demagnetize materials, and ultimately shorten the motor’s lifespan. Designers must therefore strike a balance—maximizing torque output while preventing overheating and maintaining energy efficiency.

Material Fatigue Due to Repeated Torque Load

Motors in robotics, industrial automation, or medical devices often undergo constant start-stop cycles or repetitive load conditions. This repetitive stress can lead to material fatigue, where motor shafts, bearings, or gear components wear down over time. For a small DC motor high torque design, the challenge is magnified because the compact size leaves less room for oversized reinforcements. Advanced alloys, precision bearings, and surface treatments are often used to extend durability under such demanding conditions.

Miniaturization Constraints Versus Torque Demands

One of the greatest engineering challenges is delivering powerful torque in increasingly smaller packages. Devices such as surgical tools, laboratory instruments, and consumer electronics demand ultra-compact motors, yet their torque requirements continue to rise. Achieving this balance requires innovation in magnetic materials, coil winding technology, and gear reduction systems. For many applications, the limiting factor is not torque potential but the physical constraints of size and weight.

Cost Versus Performance Trade Offs

While cutting-edge designs can push the limits of torque density, they often come at a higher price. Rare-earth magnets, high-temperature materials, and precision manufacturing increase costs. Engineers and buyers must carefully weigh the trade-off between performance and affordability. In mass-market consumer devices, cost sensitivity may dictate the use of simpler brushed motors, whereas in critical medical or aerospace systems, investment in premium High Torque Small Motor solutions is justified by safety and reliability needs.

In short, designing a small high torque electric motor that combines power, efficiency, durability, and affordability is a delicate balancing act. Overcoming these challenges requires not only technical expertise but also strategic decisions based on application priorities.

6. How to Choose the Perfect Small DC Motor High Torque Model

Selecting the right small DC motor high torque model is not simply a matter of picking the motor with the highest specifications. Instead, the process requires a structured evaluation of the application, electrical conditions, and long-term operating needs. By following a systematic approach, engineers and buyers can ensure that the chosen High Torque Small Motor delivers reliable, efficient, and cost-effective performance.

Define the Application Requirements

The first step is to clearly outline the motor’s role in the system. Consider the load type:

Constant load, where torque demand remains steady (e.g., conveyor belts).

Variable load, where torque fluctuates during operation (e.g., robotic joints).

Intermittent load, where torque is needed only at certain intervals (e.g., medical dosing pumps).

The duty cycle is equally important. Will the motor run continuously for long hours, or only occasionally for short bursts? Continuous operation places higher demands on durability, thermal management, and efficiency, while occasional operation may allow for simpler designs.

Calculate Torque Demand

Accurate torque calculation is critical. Torque can be estimated using the load’s mass, the radius of motion, and the required acceleration. For applications requiring high reliability, it is advisable to include a safety margin of 20–30% above the calculated torque.

This ensures that the small high torque electric motor is not constantly operating at its maximum capacity, which reduces wear, prevents overheating, and extends service life.

Match Motor Type with Use Case

Different applications benefit from different motor technologies:

Brushed DC Motors: Ideal for cost-sensitive or simple projects where budget is a priority and moderate lifespan is acceptable.

Brushless DC Motors (BLDC): Best for applications needing high efficiency, precision, and longevity, such as drones, surgical devices, or laboratory instruments.

Gear Motors: A perfect choice when compact torque enhancement is needed, such as in door locks, actuators, or portable tools.

Stepper Motors: The right option when positioning accuracy is crucial, such as in measurement equipment, 3D printers, or automated lab systems.

By matching motor type to use case, engineers ensure that the High Torque Small Motor meets functional expectations without unnecessary cost or complexity.

Consider Power Supply Constraints

A motor’s performance is tightly linked to the available power source. Check the system’s voltage levels—common options include 5V, 6V, 12V, and 24V. Ensure that the selected small DC motor high torque design is compatible with these levels.

Additionally, consider the current limits of the controller, driver, or battery system. Motors with high torque demand higher current, and if the power supply cannot deliver, performance will suffer. In some cases, upgrading the driver or using current-limiting circuitry may be necessary.

Factor in Maintenance and Lifecycle Costs

Motor selection is not only about technical fit—it’s also about long-term economics. For example:

Brushed motors may require brush replacement and generate more noise, but their lower purchase price makes them attractive for budget applications.

BLDC motors are more expensive upfront, but their long service life and low maintenance make them cost-effective for critical systems.

Noise and vibration should also be factored in, especially for consumer devices, medical equipment, or laboratory instruments where user comfort and precision are essential.

7. Practical Tips for Optimizing Motor Performance

Use Proper Motor Drivers and Controllers to Prevent Overload

One of the most common causes of premature failure in small DC motor high torque applications is electrical overload. Motors require drivers and controllers that are matched to their current and voltage needs. Using an undersized driver can lead to overheating, tripped circuits, or reduced torque output. Conversely, an oversized driver can increase costs unnecessarily. Selecting the right control electronics ensures smoother operation, prevents overload, and improves motor lifespan.

Ensure Correct Gear Ratio Selection to Maximize Torque Without Overheating

When torque requirements exceed what the motor alone can provide, a gearbox is often added. However, improper gear ratio selection can cause excessive strain, leading to overheating or mechanical wear. For example, using too aggressive a reduction ratio might provide torque but at the cost of speed and efficiency. Engineers should carefully calculate gear ratios that balance torque, speed, and thermal limits to get the most from a high torque small motor without pushing it beyond its safe operating range.

Regular Maintenance Checks for Mechanical Wear

Even compact, modern motors are subject to mechanical wear, especially in high-duty applications. Bearings, gears, and shafts may degrade over time, particularly under repeated torque loads. For miniature brushed DC motors, brushes are a consumable component that gradually wears out during use. Since these brushes are typically not replaceable, the entire motor must be replaced once brush wear reaches its limit. Scheduling regular system-level maintenance checks helps detect early signs of wear in gears, bearings, or motor assemblies. By proactively monitoring the condition of a small high torque electric motor, operators can extend the service life of the overall system and ensure long-term reliability.

Employ Torque Sensors for Feedback in Critical Applications

In high-precision or safety-critical environments, guessing is not enough. Integrating torque sensors into systems allows real-time monitoring of load conditions. This feedback ensures the small DC motor high torque is neither underutilized nor overstressed. In applications such as medical devices, robotics, or laboratory equipment, torque feedback can prevent malfunctions, improve accuracy, and enable predictive maintenance strategies.

Conclusion

Selecting the right high torque small motor is no longer just a matter of size—it is about balancing torque, efficiency, durability, and integration with the system it powers. From robotics and medical devices to consumer electronics and industrial automation, the role of small high torque electric motors is expanding as industries demand compact yet powerful motion solutions.

By understanding torque fundamentals, comparing motor categories, and analyzing key parameters such as speed-torque curves, thermal limits, and gear ratios, engineers can make smarter choices. Likewise, considering application-specific requirements, power supply constraints, and long-term lifecycle costs ensures that the selected motor will not only meet performance expectations but also deliver reliability over time.

For engineers, product designers, and decision-makers, the key is clear: choose with precision, optimize with care, and think ahead to future trends. A well-chosen high torque small motor is not just a component—it is the power core that drives performance, reliability, and innovation in modern devices.

Frequently Asked Questions (FAQ)

Q1: What is a High Torque Small Motor?

It is a compact electric motor designed to deliver strong rotational force relative to its size, widely used in robotics, medical devices, consumer electronics, and industrial equipment.

Q2: How is torque different from speed?

Torque is the rotational force a motor produces, while speed is how fast the shaft spins. Applications that require lifting or pushing power usually need small high torque electric motors rather than speed-focused designs.

Q3: Can miniature brushed motors be maintained?

Most miniature brushed DC motors have non-replaceable brushes. Once worn out, the entire motor must be replaced, making proper load management important for lifespan.

Q4: When should I use a brushless motor?

Choose BLDC motors when you need high efficiency, long service life, and quieter performance, especially in precision or medical equipment.

Q5: How do gearboxes improve torque?

A gearbox reduces speed and multiplies torque. Correct ratio selection maximizes performance, while improper ratios can cause overheating or wear in a small DC motor high torque setup.

Key words:

Recent News